Packaging Solutions

Packaging Solutions

Innovative packaging solutions are central to the service that Zip-Chem® Products provides to the aviation industry.

Over the last 20 years, Zip-Chem® Products has developed packaging and packaging technology to:

-

- Reduce financial costs

- Reduce waste

- Ease product application

- Minimize environmental or occupational exposure

- Ensure that mix ratios are accurate

- Optimize Labor

Packaging Types

Zip-Chem® Products adapts package designs from other industries and invents new products to meet the needs of the aircraft maintenance markets.

Zip-Chem® Products currently partners with Andpak, a Morgan Hill, CA packaging company, so that packaging solutions can be provided for Zip-Chem® ‘s chemical products.

Packaging Solution Needs

New materials in aircraft manufacturing, new and changing aviation maintenance products and procedures, and cost optimization pressure continue to create demand for new packaging solutions. Zip-Chem® Products welcomes these challenges and encourages customers and potential clients to contact the company to learn about Zip-Chem® ‘s products and solutions.

Systems For Packaging and Mixing

Systems For Packaging and Mixing

The company offers pre-mixed frozen materials and sealed two-component packaging/mixing systems. These include:

- Clip-paks(r)

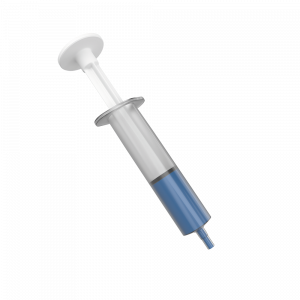

- Special Syringe Packages

- Injection

- Barrier Kits

- Combination Mixing and Application Devices, such as Two Component Syringes and Foil-Paks

Benefits of Packaging Systems

Zip-Chem® packaging systems address environmental and occupational health concerns. Some of these packaging systems include non-ozone depleting aerosol technology and simple hand pump sprays. These systems place a controlled amount of product at precisely the point of need. This strategy reduces waste and minimizes build-up.

Cartridge systems and specialized mixing and spray applicators also facilitate cost savings through bulk packaging and carefully controlled product applications.

Success of Packaging Systems

Zip-Chem® ‘s packaging systems are successful because they are flexible for customers.

Short runs in material packaging are common and encouraged.

Zip-Chem® meets a site’s needs without having to ship large quantities of product. Additionally, Zip-Chem® ‘s substantial international distribution ensures that the cost efficiencies attained while larger batch runs remain in place regardless of an individual order.

Alternative Packaging Guide

|

Application |

Packaging Alternatives | Principle Advantages | Cost Implications |

Other Advantages |

| Two-Component Coatings and Paint |

Clip-paks, Zip-Spray |

Precise Mix of Materials | Reduced Waste |

Reduces exposure and release of materials |

| Two-Component Adhesives, Epoxies, and Sealants |

Foil-Paks, Clip-Paks, Dual Syringes, and Frozen and Pre-Mixed Materials |

Precise mix of materials and product performance | Saves money on labor and reduces waste |

Reduced exposure |

| Contact Cleaners |

Aerosol and Pre-Moistened Towelettes |

Precision Application | Reduced Waste |

Minimal Product Build-Up |

| Lubricant CIC’s |

Aerosol, Cartridges, Tubes, Pails |

Precision Application | Reduced Waste |

Minimal Product Build-Up |

| Cleaners |

Pumps, Sprays, and Towelettes |

An application that is quick and convenient | Refillable containers that allow for bulk processing |

Concentrations that are predosed and accurate |